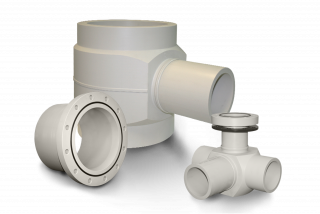

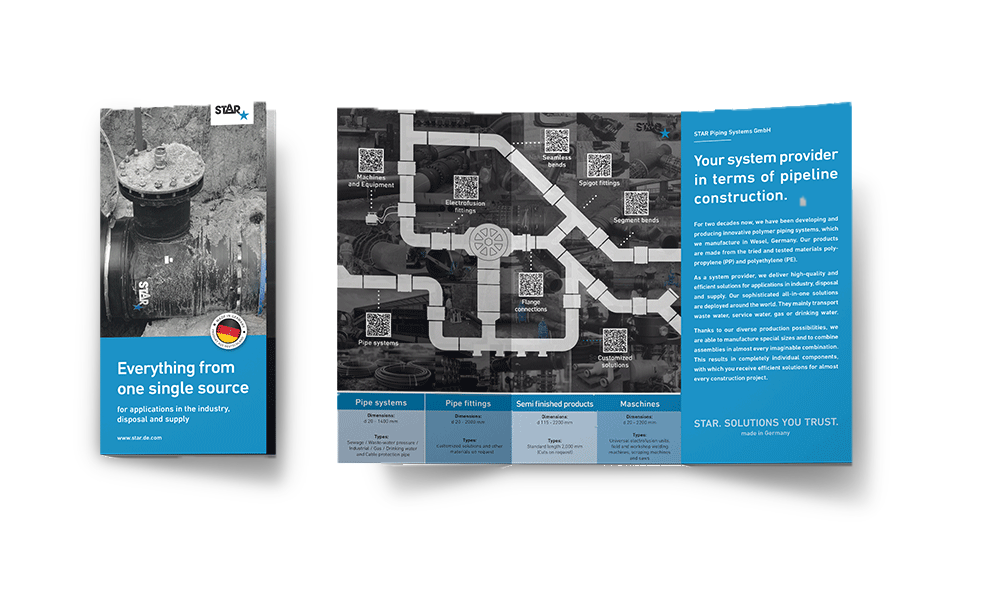

Safe infrastructure for building and civil engineering projects with plastic pipes and fittings from STAR.

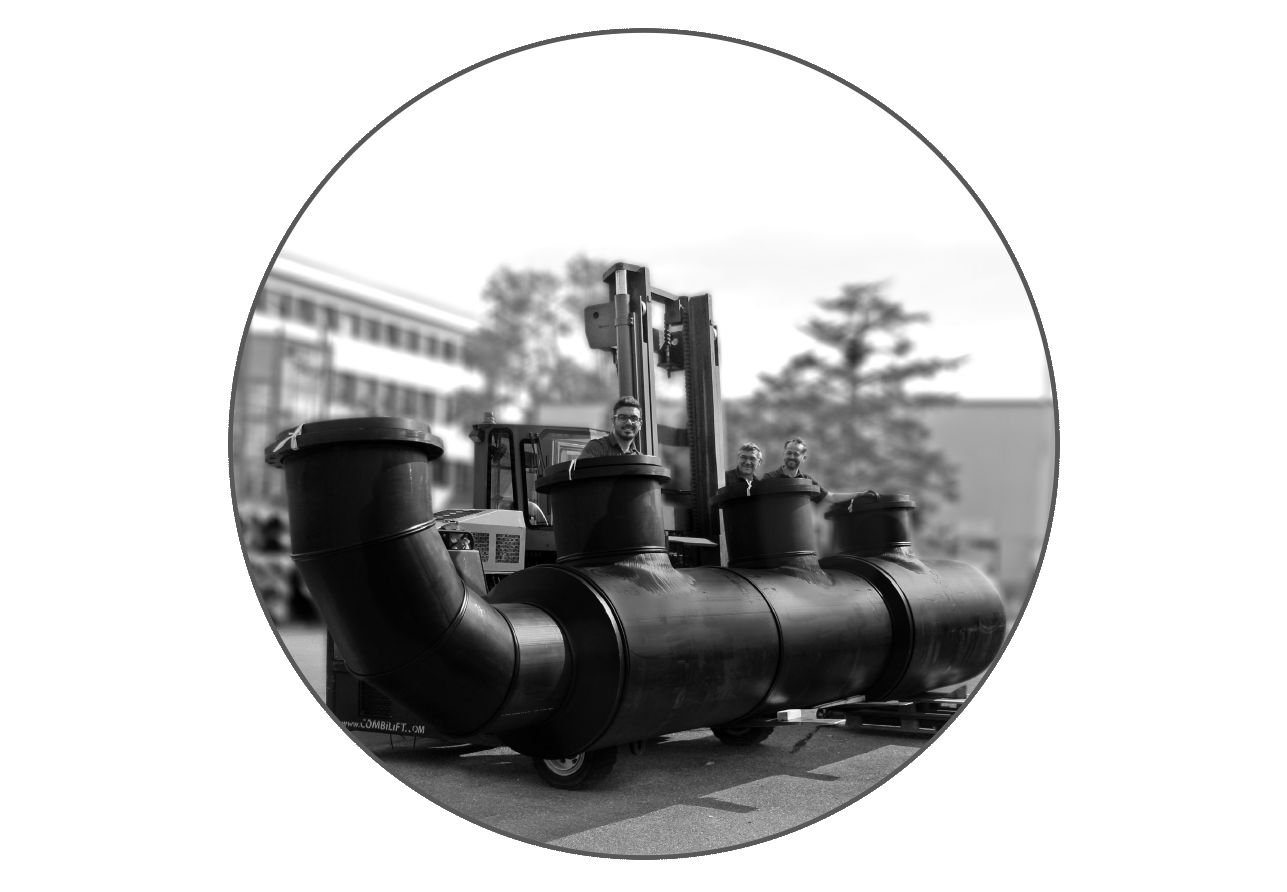

Because what matters is ensuring that it gets there – That’s exactly what we at STAR Piping Systems GmbH take care of for you while producing durable and safe pipes and fittings for industrial plant construction, as well as municipal drainage and supply networks.

STAR Piping Systems GmbH. Your system provider for piping construction.

On a production area of over 15,000 m², we produce fittings for plastic pipe systems, which you can receive customised on request, according to your individual project requirements.

Are you planning your next project?

Feel free to contact our technically trained team.

Together with you, we will develop a tailor-made solution that will meet the requirements of your construction project.

As diverse as your projects.

Plastic piping systems

from STAR

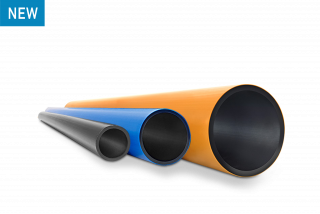

As a system provider, we are constantly expanding our product range and supply you with state-of-the-art products.

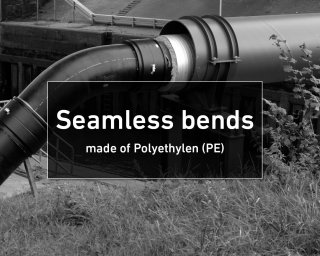

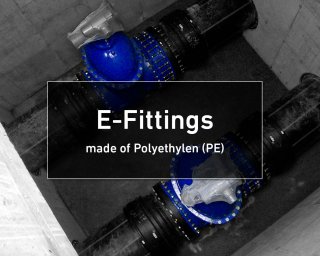

With our diverse range of products, you get the solution for the safe storage and reliable transport of a wide variety of media.

Whether waste water, service water, drinking water, gas or the safe laying of electrical lines – our extensive product range offers ideal conditions for almost every requirement.

We will be happy to manufacture the ideal component for your project! So that you can realise your building project as easily as possible.

Solutions you trust.