Допустимые отклонения

All information on our website is without guarantee.

In the interest of technical progress, we reserve the right to make changes and improvements without notice.

When manufacturing our products, we comply with the applicable standards with regard to geometric dimensions, tolerances and quality requirements.

For pipeline systems in gas supply, for example, DIN EN 1555 is decisive. In the water supply, as well as for drainage and sewage pressure pipes, the DIN EN 12201.

If you require certain tolerances, please contact us.

We would be happy to send you a customer drawing with approval.

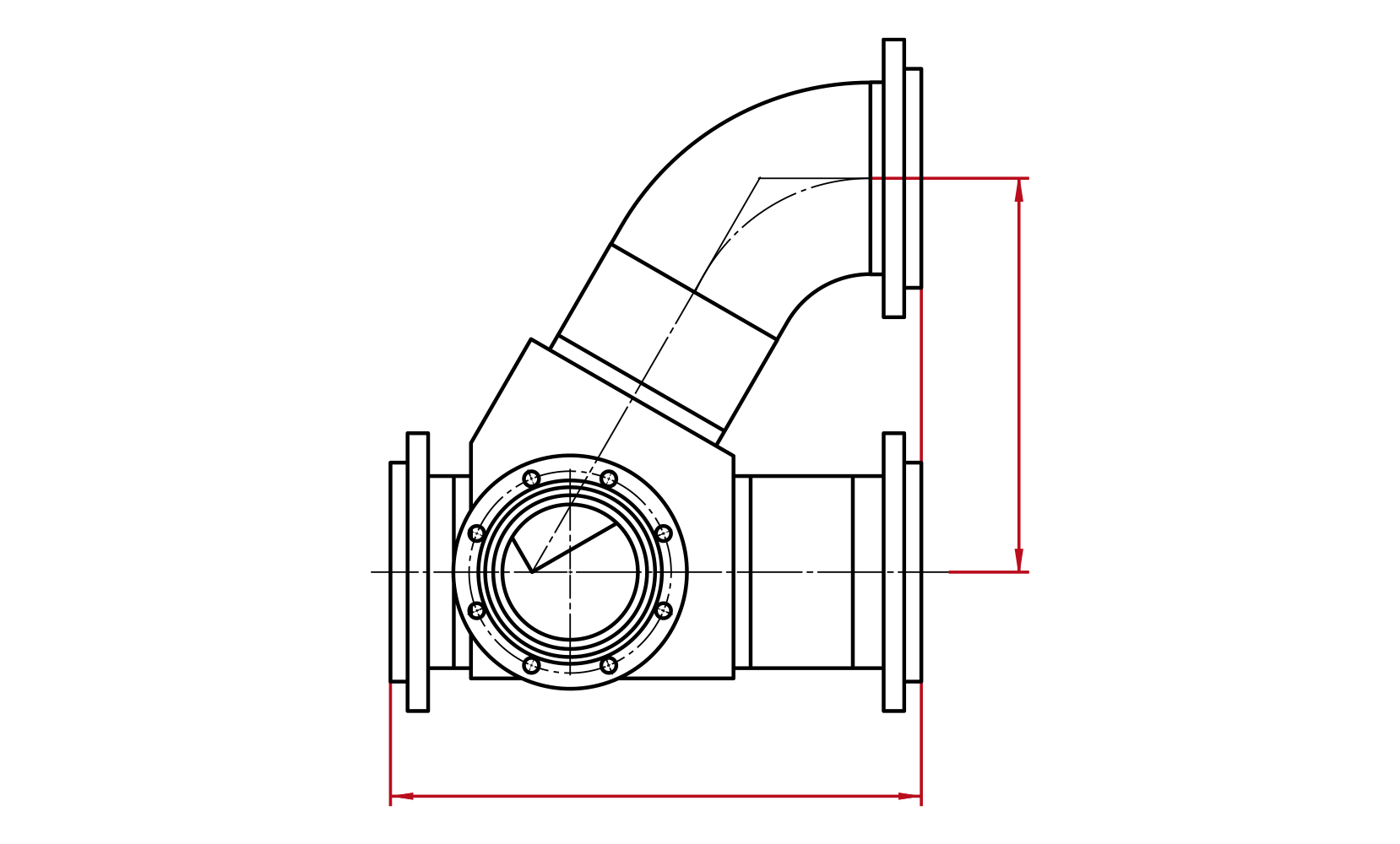

Tolerances for extension

with pipe

| d [mm] | Tolerance [mm] | |||

| ≤ 225 | ± 20 | |||

| 250 – 280 | ± 25 | |||

| 315 – 450 | ± 30 | |||

| 500 – 800 | ± 35 | |||

| 900- 1200 | ± 40 | |||

| 1400 -1600 | ± 50 | |||

| ≥1800 | on request |

Example:

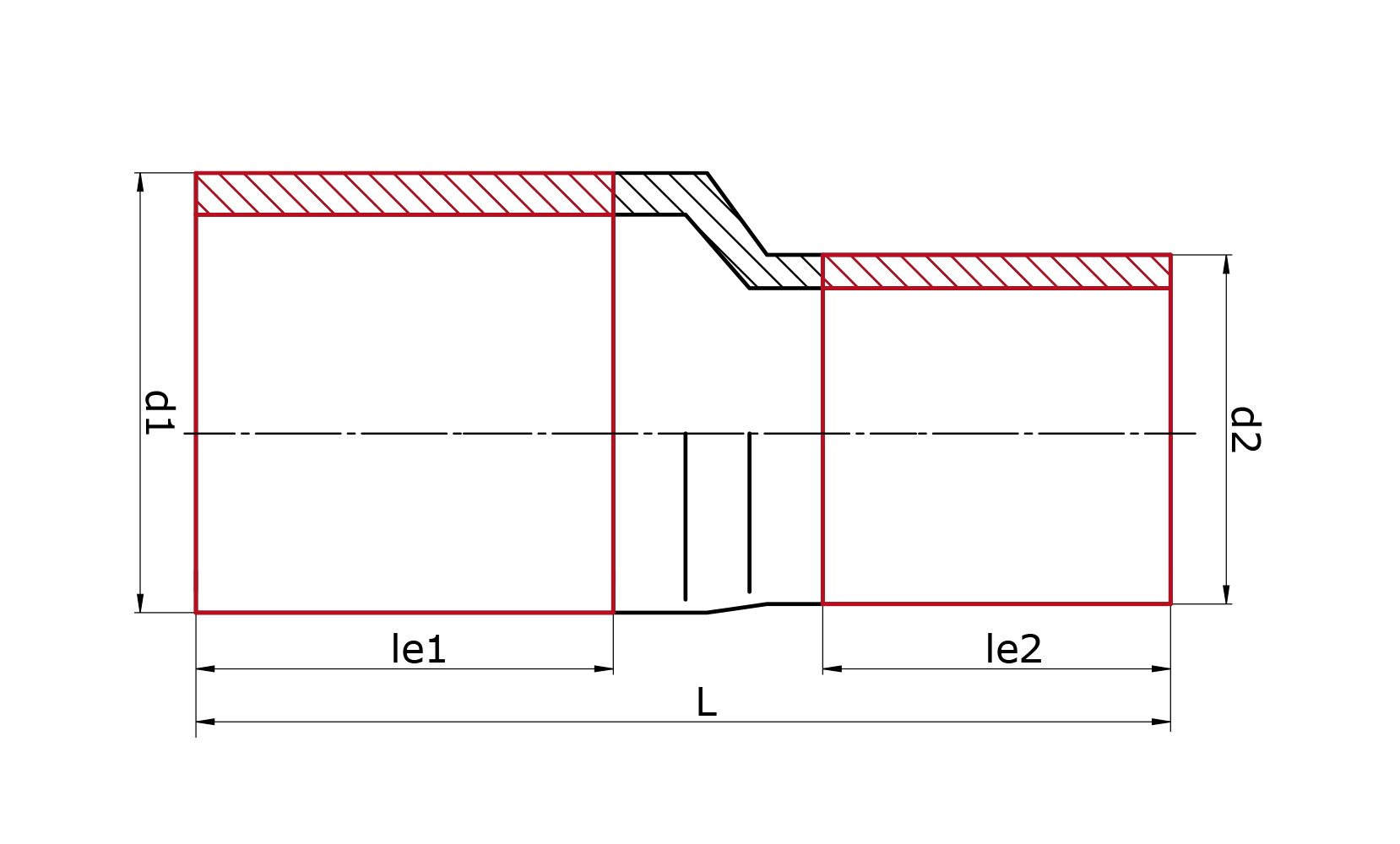

Tolerances for extension

with fittings

| d [mm] | Tolerance [mm] | |||

| ≤ 315 | ± 10 | |||

| 315 – 500 | ± 15 | |||

| > 500 | ± 20 |

Do you need certain tolerances for your assemblies?

Please do not hesitate to contact us!

Example:

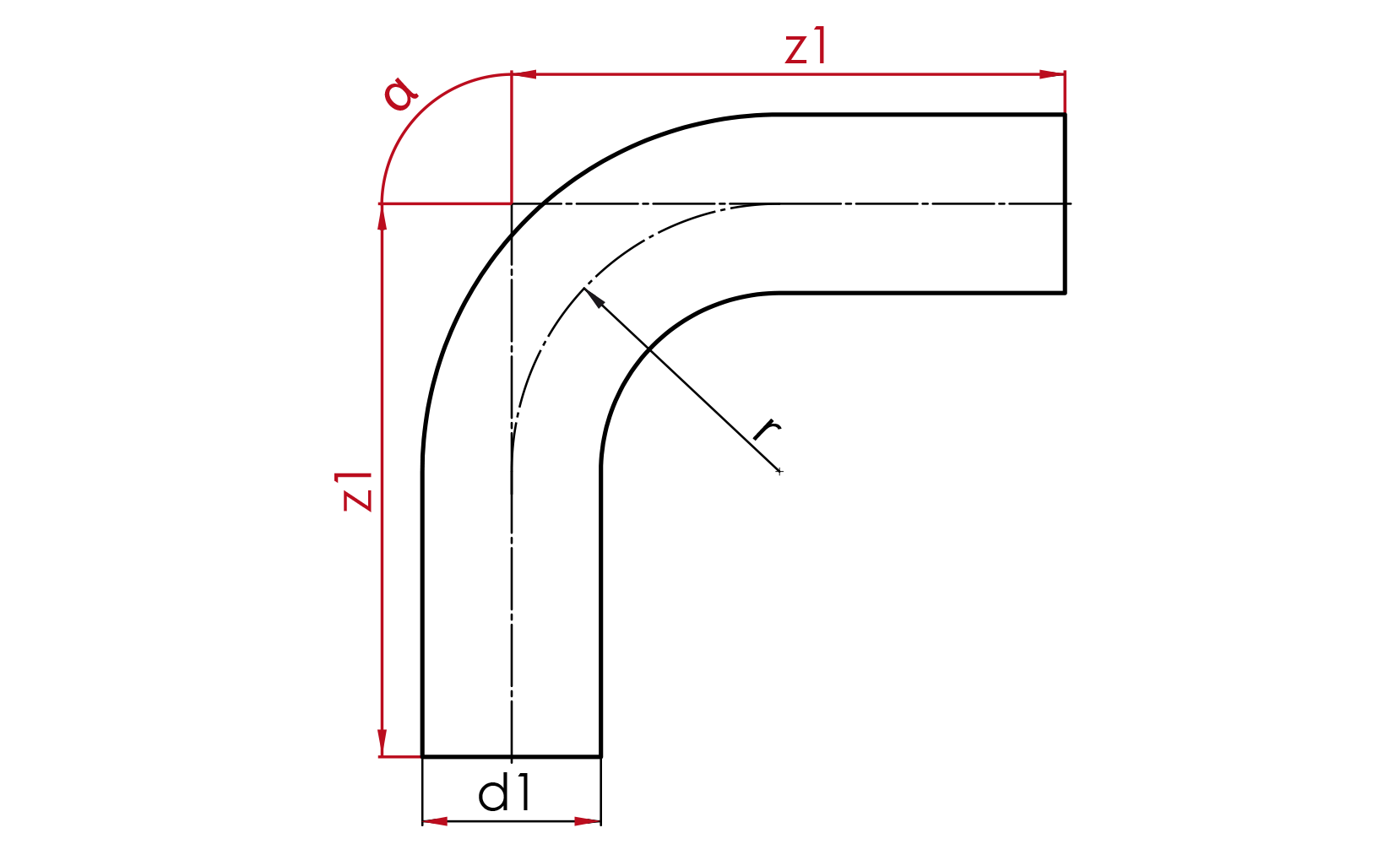

Tolerances for

seamless bends

| r / ri [mm] |

Tolerance angle [α] |

Tolerance z1 [mm] |

|||||

| r ≈ 1,5 x d | ± 5° | ± 50 | |||||

| r ≈ 2,5 x d | ± 5° | ± 50 | |||||

| r ≈ 3 x d | ± 5° | ± 100 | |||||

| r ≈ 3,5 x d | ± 5° | ± 100 | |||||

| r ≈ 5 x d | ± 5° | ± 100 | |||||

| ri ≈ 700mm | ± 5° | ± 100 | |||||

| ri ≈ 1100mm | ± 5° | ± 100 | |||||

| ri ≈ 1750mm | ± 5° | ± 100 |

Example:

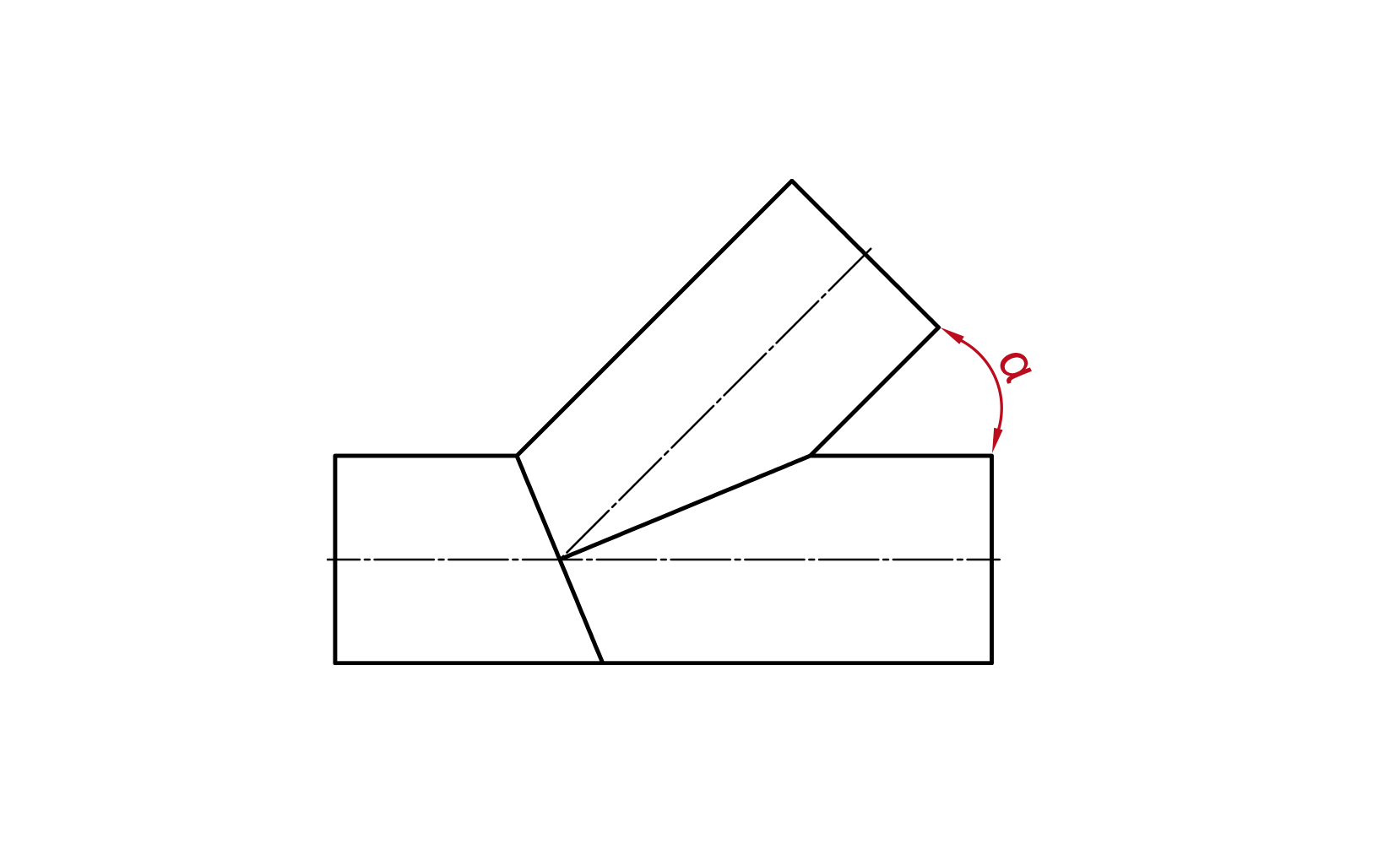

Tolerances for segment welded fittings

The following applies to the angles of

segment-welded fittings:

α = ± 2°

Example:

Weights

The weights given in the technical product data sheets serve as a guide.

Please contact us for more precise calculations (statics, transport, etc.).

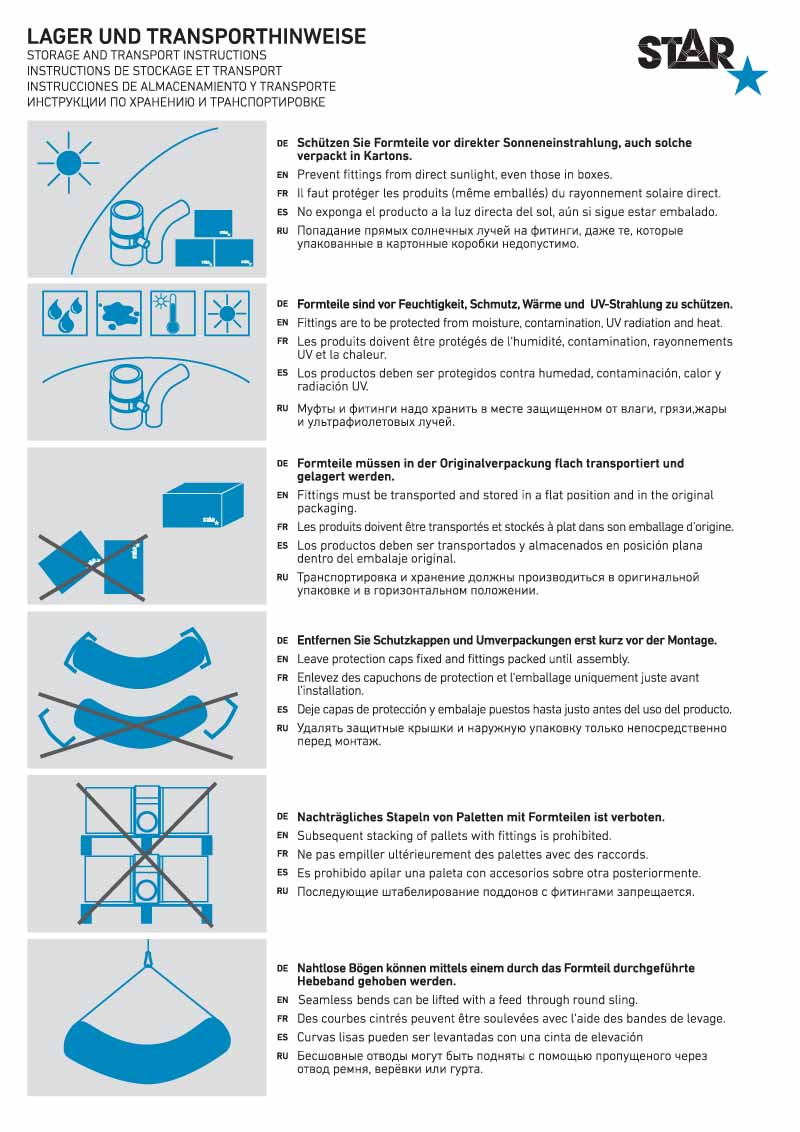

Please also note our transport and storage instructions.

Improper handling of the products can lead to deviations.