Did you know?

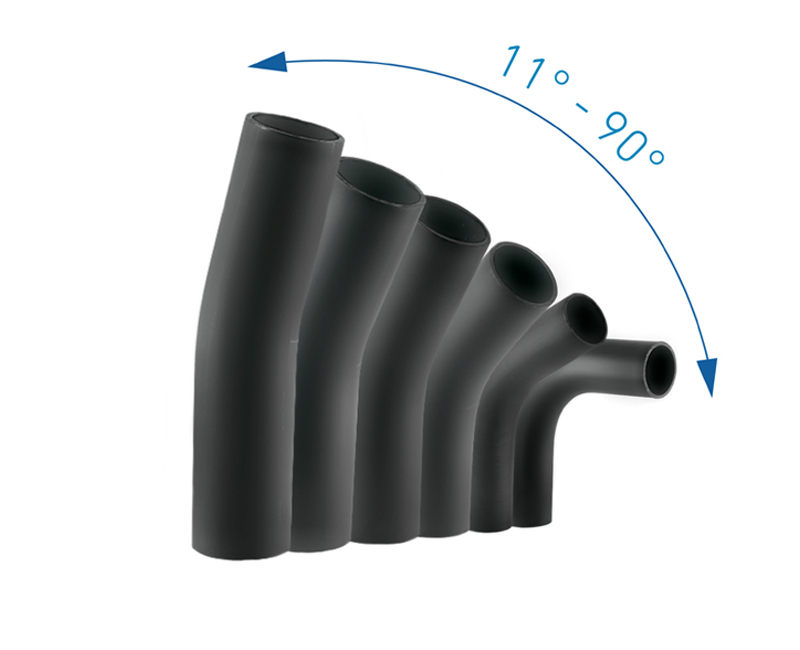

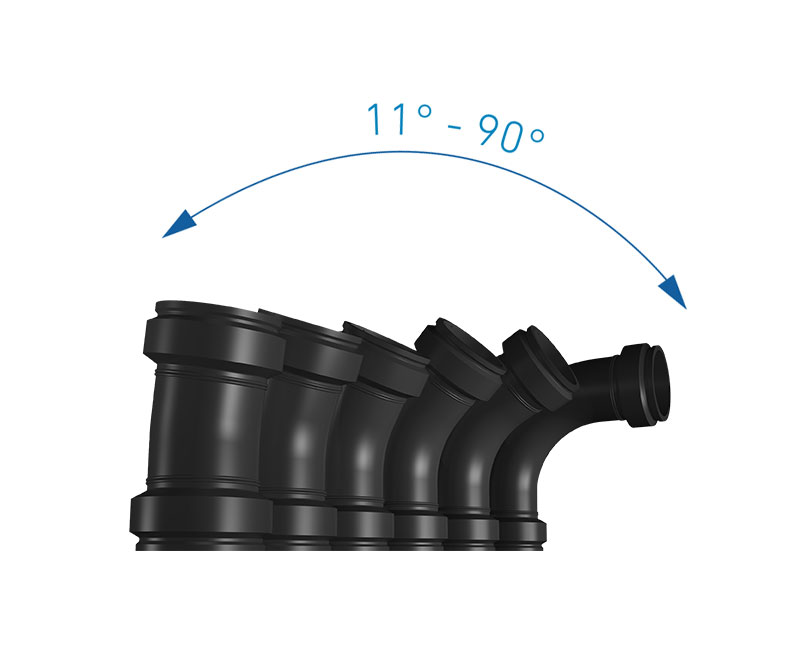

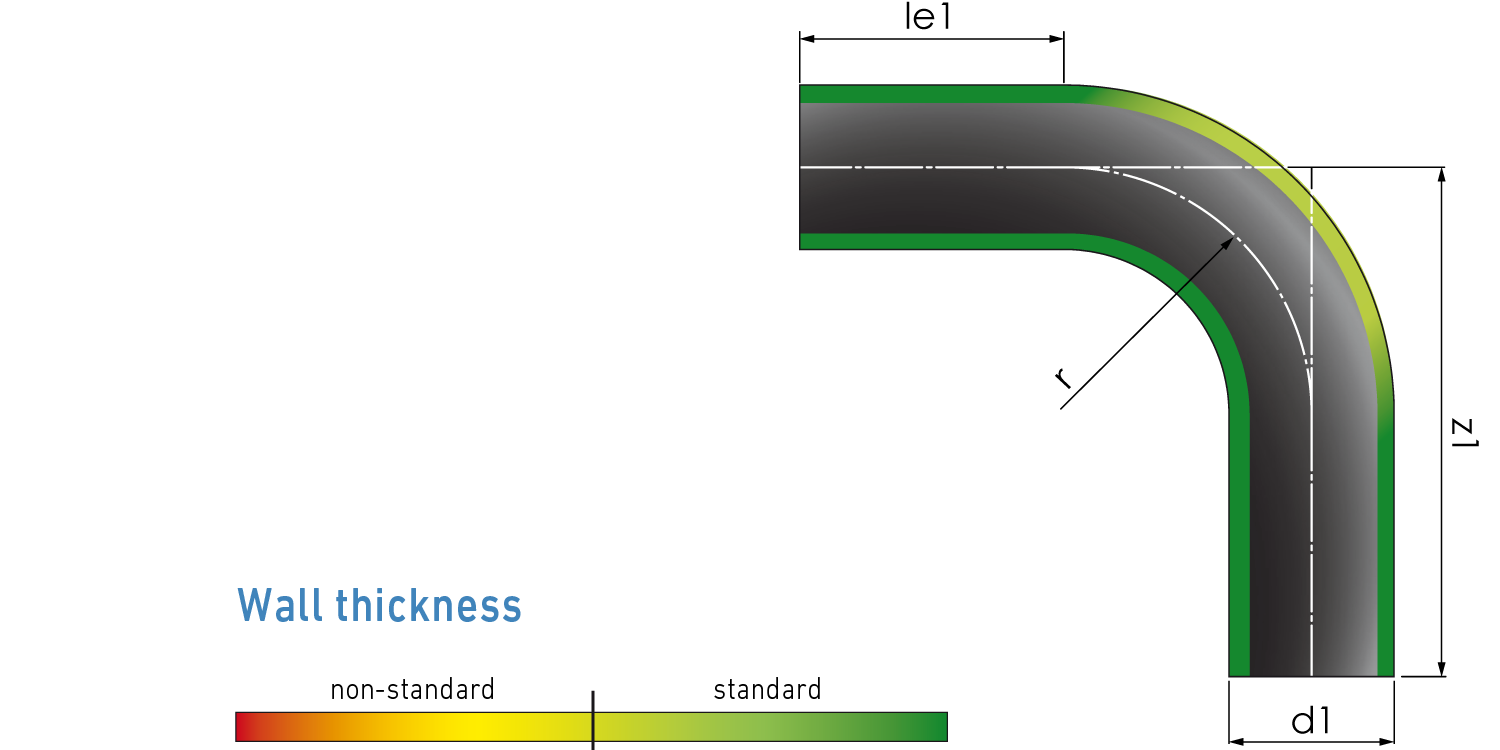

After years of research we are now the first manufacturer capable of supplying pipe bends to meet EN 12201 and EN 1555 standards. This means we can maintain the required minimum wall thickness of R ≈ 1,5 x d, thereby creating the optimum conditions for any pipe-laying project.

What is behind DIN EN 12201-3 and DIN EN 1555-3?

The standards DIN EN 12201-3 and DIN EN 1555-3 define quality standards of PE pipeline systems for the gas and water distribution as well as for irrigation and waste water pipelines.

Any dimension as well as tolerances and material properties are specified by these standards. The wall thickness of seamless bends is part of the stipulated dimensions. The ending number “3” of the standards indicate the sections that not only define the pipes but also the requirements for the finished fittings. DIN EN 12201 is the standard for water distribution, irrigation and waste water pressure pipelines, while DIN EN 1555 is the standard for PE pipeline systems for the gas distribution. Seamless bends that are conform with both standards can be used for either gas and water. This is the case with the norm-compliant seamless bends by STAR.

DVGW certified bends - taking pipe construction to a new level

While the bends comply with the standards, the seamless bend is furthermore certified by the DVGW. A product with the DVGW hallmark gives you the assurance that it is state-of-the-art and conform with established regulations. The so-far worldwide only DVGW-certified seamless bend produced by STAR stands out prominently from other seamless bends and distinguishes itself verifiably by a considerably long lifetime and high reliability.

By guaranteeing the minimum wall thickness, standard-compliant DVGW-certified seamless bends by STAR provide highest safety and enable pipeline construction according to standard, meeting highest demands.