Our small, decisive three-strong team meant that we could put this into practice immediately – and we have been growing the vision to this day. Even now, 20 years later and with many more employees than ever, we still have that vision from 1995 as the first point on our agenda, and work with our skilled team and innovative ideas to keep achieving visionary goals.

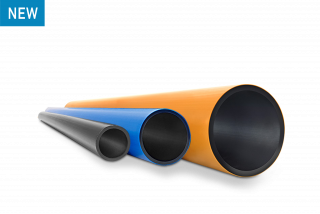

For two decades now, we have been developing and producing innovative polymer piping systems, which we manufacture on Schepersweg in Wesel, Germany. Our sophisticated all-in-one solutions are made of polyolefins and are deployed around the world. They mainly transport gas, drinking water, service water or waste water.

Our quality standards are exceptionally high. After all, our products have to transport clean drinking water and keep gas systems completely safe. We primarily ensure quality via our DIN EN ISO 9001:2008 quality management system. In addition to providing expert advice and personal support from direct contacts within the company, flexibility is also at the heart of what we do. This is reflected in the precisely tailored solutions that we provide to individual construction projects.

We take the environment and sustainability seriously. This is evident on the roof of our production area, which covers more than 9,000 m2 and includes divisions specialising in extrusion, machining, fittings, and the production of electrofusion couplers and e-fittings. The roof is equipped with a state-of-the-art photovoltaic system that produces the majority of the electricity we use. In the colder months, our buildings are heated with waste heat from the extrusion machines. This environmentally friendly approach to production means that we are significantly reducing harmful emissions over the long term.

As a medium-sized enterprise, we have long since recognised what the demographic change means for us, so we are keen to train our future experts in-house. We currently have 12 young people pursuing vocational qualifications in six different occupations across the technical and commercial sectors. This means we are actively working to prevent the impending skills shortage. We are setting a good example. For us, education and training is a socio-political matter of course. We also have our own training workshop so that our young people can get the skills they need to be fit for the future.

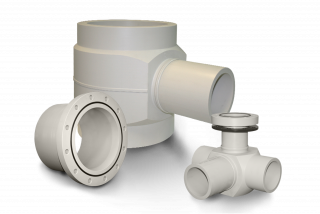

We believe that our reliability and the loyalty of our customers have made us what we are today: a successful, medium-sized enterprise that offers a comprehensive range of plastic fittings.